AR Maintenance 101 by David Bock

Guns are fairly intricate mechanisms. While they can go long periods with minimal maintenance and no issues, it’s a good idea to know how to maintain them beyond a simple cleaning.

Since the AR family of rifles is probably the most popular semi-automatic rifle in the country right now, I’d like to discuss some of the malfunction causes and solutions that the average owner can take care of at home.

The heart of the AR is its gas system, commonly referred to as gas impingement. In this system, gas is diverted from the barrel and fed back into the gas key on the bolt carrier group. This channels the gas into a chamber behind the bolt, pushing the bolt forward and the carrier back. Since the bolt can’t move forward, being locked into the barrel extension, the carrier has to move back. This movement causes another component, called the cam pin, to rotate and unlock the bolt. The bolt and carrier then move back together during the action cycle.

All of this is very dependent on a few components being in good repair and properly set. Specifically the gas key bolts need to be properly tightened and staked and the gas rings need to be within spec and replaced when they wear enough to cause function issues.

Happily, most carriers come with the gas key bolted down and properly staked. Unfortunately, not all of them are. Knowing the signs of gas key leakage or worn gas rings and how to remedy the situation can prevent your rifle from being transformed into a really awkward straight pull bolt action.

Gas Key

If the gas key bolts are not properly tightened and staked, they can loosen during the firing cycle. This allows gas to leak out around the base of the gas key and rob the system of pressure, leading to short stroking of the action, feeding issues, and failure to lock open on an empty magazine.

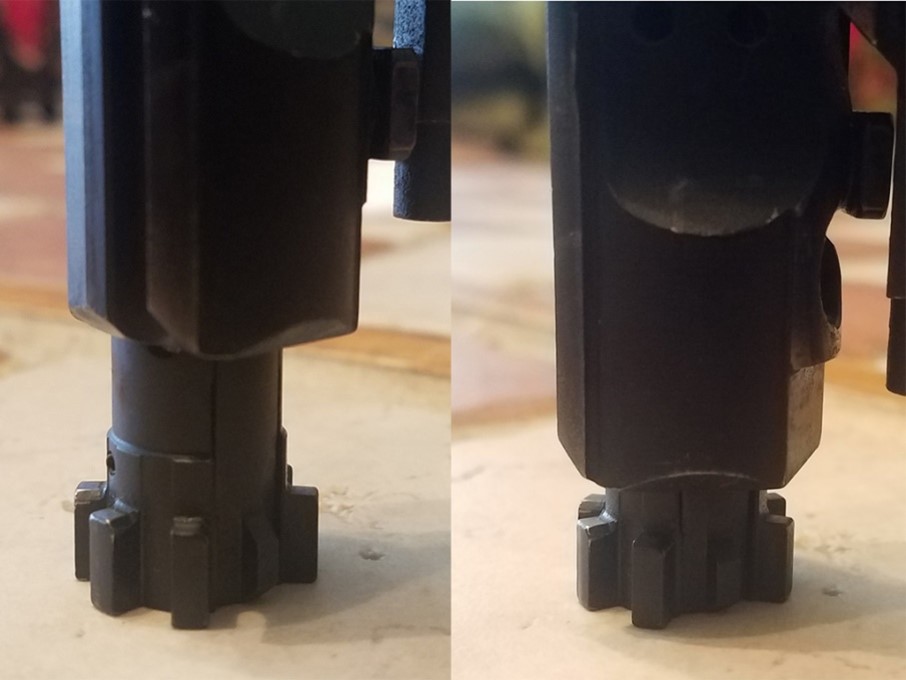

A replacement gas key won’t be staked and will look similar to this one.

If the gas key is loose, don’t just tighten the screws and call it a day. The key needs to be removed and the mating surfaces thoroughly cleaned before reassembly. Once that’s done, the bolts need to be tightened and properly staked.

There’s no need to really crank down on them. Firmly hand tightened with a proper bit driver is all that’s needed. Once this is done, it’s time to stake the bolts. No special tools are needed for this job other than a center punch. I prefer an automatic center punch like this model from JelBo, though a manual center punch and ball peen hammer can work just as well.

Make sure the carrier is properly secured. I use a bench vice with padded soft jaws, but a couple of pieces of wood clamped to a table can suffice.

All that needs to be done is to displace a small amount of metal from the gas key into the head of the bolt to prevent it from turning under vibration. Don’t go crazy.

This is one in my collection. The first attempt at staking turned out to be insufficient, so it had to be done again. That’s why the staking looks more messy and aggressive.

In case anyone was wondering, I’m not a fan of thread locker on firearms. There may be some instances where it’s warranted, but much less than it’s used. If you must use some kind of thread locker on a firearm, blue shalt be the color thou shalt use, and the color of the thread locker shall be blue. Green shalt thou not use, nor either use thou red. Black is right out.

Gas Rings

The gas rings on an AR bolt, like the rings on a car engine cylinder, add a gas seal as well as some friction to the system. Every time the bolt cycles, they rub against the inside of the carrier and wear. Gas rings, like springs, are consumable parts and will need to be replaced eventually. The signs are similar to a loose gas key, but there’s a simple test to check the gas ring friction.

After removing the bolt/carrier group from the rifle, make sure the bolt is in the forward position and gently stand it up on the bolt face. If the carrier stays up, the rings are fine. If it slides down the bolt, it means the rings are sufficiently worn to require replacement.

The bolt requires three rings and they are usually sold in convenient three packs, like these from Brownells.

Remove the bolt from the carrier and wipe off any grease, oil, or loose carbon. Using a knife point or sharp pin (do not use the firing pin) find the gap in the rearmost ring and pull it towards the tail of the bolt, stripping the ring out of the retaining groove on the bolt. Repeat for the other two.

Clean the retaining groove and replace the rings. Don’t worry about the gaps in each ring lining up, the first time the bolt cycles they’ll shift around. Lubricate the bolt and reassemble. There should be a noticeable increase in friction.

Remember, take care of your tools and they’ll take care of you.

I’ve always been taught to not alight the gaps in the gas rings

LikeLike

Allegedly self-correcting issue. However, having had it tattooed on my brain by good Drill Sergeants, I habitually, stagger the gas rings when cleaning.

LikeLike

same

LikeLike

Ditto

LikeLike

C4C

LikeLike

Sarah: Informative and very useful for those who are hoping for the best but anticipating the worst. Thank you for including it on your site.

LikeLike

I’m not sure thread locker color coding is consistent, so it would be nice to see the comment about what colors are right expressed in terms of what types are right. There are weak/medium/strong thread lockers, as well as specialized ones like wicking type or bearing lockers. I vaguely recall green is one of the latter but I certainly would not swear to it, nor would I necessarily expect Loctite and its various competitors all to use the same colors.

LikeLike

The short list for loctite thread lockers:

242: Blue, medium strength. Can be disassembled, with work

209: Green, wicking, best for bearings

271: Red, high strength. Needs heat so disassemble

222: Purple, low strength.

Henkel has a website with all of their threadlockers (and everything else they sell on line) on it. Warning: something about the site kills Pale Moon, once to the point where I had to employ the BRS and reboot the linux box. OTOH, Firefox is OK with it. No idea on other browsers. https://next.henkel-adhesives.com/us/en/applications/threadlockers.html

FWIW, there are a boatload of various blockers. 242 and 271 usually show up at Home Desperate and similar outlets. I got a bottle of 222 from a surplus place 25-30 years ago. I don’t use it much, but it’s still usable. For the more exotic types, see Grainger or Ye Local Industrial Supply House. (Or Henkel dot com…)

LikeLike

Scraping the bolt and bolt carrier free of carbon:

You can find all sorts of gadget$$$ to scrape the things, or, you can make a tool from clothes hanger wire:

Note again: don’t use hardened steel like a real screwdriver, dental pick, or knife. The removable cap from a Bic pen or similar can sometimes work, if hard enough.

And to cut the carbon chemically, if it is epically caked, use Liquid Wrench or Kroil. -Dont- get that stuff on the plastic parts.

The gas tube can be cleaned with a special full length pipe cleaner. Make sure you leave no bits in it. And no solvents, etc. If nothing else is available, blow it clear with compressed and dry air. US GI blanks are notorious for fouling gas tubes, and .22LR converters dump all sorts of crap in the gas tube (lead bits, parafin bits, and whatever coal tar is used in that cheap import 22 ammo.)

LikeLike

Thank you, Mr. Bock. I had been lazy in my reading and had never investigated the meaning of staking your bolt carrier group /gas tube screws.

LikeLike

The most interesting thing about the AR-10 design is even though it gets described as a direct impingment action, what Stoner really did was package a short stroke gas piston action inside the bolt carrier group.

The up shot is everything is moving on the same line, and that line goes directly along the stock. Makes it extremely controllable, even under full auto, because you are just dealing with the recoil, and not so much vertical twist as you get in concentrational actions.

And means you need to do all the maintenance you would normally do in a tight gas piston, just not labeled as such because clearly it’s direct impingment and the gas seals at the back of the bolt surely can’t be that big of a deal…

LikeLike

This reminds me that I need to actually clean my guns. Haven’t used any of them very much in recent years, so they’re not what anyone would call filthy; they mostly just sit there in the safe. But they’d probably appreciate being cleaned following what little use they have seen, and being clean and oiled would help ensure that they’re un-rusted and in working order if I need them in an emergency. (Confession: I have never actually cleaned my AR.) 😬

LikeLiked by 1 person

I need to Learn how to clean our guns. I’ve watched dad (in distant past) clean his old revolvers and the rifles, not as complicated. Hubby and son got them out (dredged them up) and cleaned everything when we dispersed the firearms to my sisters for mom. Right now hubby or son clean my S&W when they clean the other 9 mm and 380’s. I really need to learn how.

In other news. I’m now hitting the target I’m aiming for 100% of the time. Even in the big circle if not always at the center that I’m aiming for (hitting there too, just not consistently). Huge improvement. Just need to keep practicing so that I can start grouping where I am aiming. S&W doesn’t seem as heavy, nor does it seem to have the same kickback, as it had at first. (I know it hasn’t changed. Just my perception.)

LikeLike

(Grin)

Toldya.

(grin)

LikeLiked by 1 person

Just remember, trigger control is most of accuracy; sight picture is far behind. Some will dispute that, but the experience of quite a few master-class shooters agrees with it.

LikeLiked by 1 person

I should note that that applies mainly to handguns; it’s important for rifles, but less so.

LikeLike

Yes. My trigger control is what is improving, not how I sight the gun.

LikeLike

Thanks for timely, useful, and accurate advice.

LikeLike

All of your stored guns should be cleaned and oiled at least once a year. To be frank, all of your functional guns should be shot at least once a month, then cleaned and oiled. After all, what’s the sense of having them if you don’t stay in practice?

LikeLiked by 1 person

Getting all that lake silt out of the firearm is a pain….

LikeLiked by 1 person

Right? So many tragic boating accidents, so many heirlooms lost to the deeps…

[sob, sniffle…]

LikeLike

Related, as in, why you want to keep your AR clean.

This Sunday, our little country church had some excitement when we realized there were cop cars parked nearby and cops moving here and there. Someone had fled from the cops, down our dead end street, abandoned his vehicle and run off. None of us saw him and church went on as usual.

I learned today they caught the guy. OK, the grandson of one of our members caught the guy. He’d been spotted running behind her daughter’s house. The cops searched the house, twice, and found nothing. Later, the family dog went berserk, yapping like crazy at a bedroom door. So the grandson took his boom stick (make and model unknown) and entered the bedroom, where he found the guy under the bed. (In fairness to the sheriff’s dept, nobody knows if he sneaked in after the search).

Grandson held guy at gunpoint until the cops arrived and took over. Bet you don’t hear about that from the gun control crowd.

Meanwhile, good dog. Good dog.

LikeLiked by 2 people

All of this.

LikeLike

Very good information – thanks!

As I was involved with a lot of ‘training’ over the years, this video was one of my resources: https://www.youtube.com/watch?v=xW4DQ5QlwrA

It’s a good idea for anyone to have maintenance tools, manuals and materials for any equipment you work with and rely on. If you don’t have specific manuals for something, often they can be found on the web.

LikeLike

Thanks for this, David. The Reader recommends you do Glocks next.

LikeLike

Nobody cleans Glocks. And they need darn little lubrication, though some is a good idea.

But if you must …

LikeLike

That said, I just cleaned off my carry gun; it was dusty, all around.

LikeLike

The Reader cleans his Glocks after every trip to the range. Good habits, you know.

LikeLike

had a gas key get knocked off the bolt carrier from using too short of a buffer on too long of a buffer tube so be careful when building

LikeLike

oopsie

LikeLike

There’s a business in town, 2A Tactical, that specializes in AR platforms. They even hold a build class every month for a dozen people lucky enough to get into them.

LikeLike

That is a good time to replace the sub-standard screws marked “YFS” (as in the above photo). At best, they may be grade “5”, but more likely they are closer to grade “2”. Either way, over time they will stretch or shear off. Then bad things happen.

LikeLike

Last year I had the gas tube come loose from the barrel. I tightened it up again, but that’s another thing to put on the “check whilst cleaning” list.

LikeLike

Eugene Stoner was a genius, who managed to cram mutually contradictory specifications into a package that can be easily and cheaply mass produced.

Kudos to him.

That said, I carried around an M16A2 for four years, and I *hated* the fricking thing. I could nitpick about the extractor and the trade-offs implicit with direct impingement, but that’s rationalization. The three things I hated were: The wobble, the ergonomics, and the lack of reliability.

The wobble. Everyone who’s picked up a variant knows what I’m talking about. The upper receiver and the lower receiver are held together with two pins, and the linkage is loose enough that the current and stock can freely twist in opposite directions by a significant amount. (It was about 20 degrees in the service rifle. Civilian gear seems to be much less offensive.). While it’s adequate to the task, I do not like depending on a tool that feels flimsy.

The ergonomics are generally a selling point of the rifle. To be clear, the safety and magazine release are excellent. My beef is that the design of the rifle actively interferes with the shooter’s ability to utilize the internet accuracy of the firearm. The first aspect of that is the straight stock lacks landmarks, so getting a consistent cheek weld is difficult. A small piece of scotch tape makes a nice field expedient fix for this. The second aspect, is that for a natural point of aim, all four points of contact should be as close as possible to a straight line directed at the target. The AR-15/M-16 etc. is almost the opposite of this. The eye relief is high, the trigger hand low.

As for reliability, I guess the civilian versions are better. And using magazines that aren’t 20+ years old certainly helps. I may know that intellectually, but I can’t help but remember all the jams I had and witnessed during critical moments. (Thankfully only during training. The flag didn’t go up on my watch.) I simply cannot trust that it’ll fire more than once.

All and all, I ‘d much rather rock a mini-14.

LikeLike

Wow. Neither M-16A1 issued to me (mid eighties) -ever- jammed. Not even with blanks. First one was an original GM Hydromatic “M16” (Early Vietnam-era) altered to “-A1” format and re-stamped as such. It still had the early bullseye forward assist, not the later A1 odd-looking toggle.

Upper/lower fit on both were not “solid”, but miniscule wobble. A bit of folded cardboard under the rear post, compressed to seat the lock pin, removed the slight wobble.

Ok. -maybe- I knew a little bit more about the weapon than the instructors taught trainees at Fort Benning. (Grin)

Others with frequent live ammo jams were cured with good magazines. (Blank jams were usually a loose blank adapter, then worn out or bent-lipped “training” magazines.) Bent/worn/abused feed lips on magazines were definitely a problem, but easily cured.

Gadzooks did I just show my age. Sheesh….

LikeLike

There is a cure for that: it’s called exposure therapy.

LikeLike

“Civilian gear seems to be much less offensive.”

This sentence reminds me of the meme with a happy Anna labelled “Civilian” and a concerned or scared Elsa labelled “Veteran”, titled “Learning that something is ‘military grade'”!

LikeLike

‘Military Grade’: built as cheap as possible by the lowest bidder.

A couple of Murphy’s Laws Of Combat detail some issues with ‘Military Grade’.

LikeLike

Military issue: “Here is your weapon. Next!”

Civilian purchase: “This AR is only 1MOA accurate. I want to exchange it for one that -works-!”

LikeLike

For removing the gas rings, wouldn’t you want a pair of snap-ring pliers with real fine points? Picking at ’em with a knife blade would just spin ’em round and round.

LikeLike

If you have them already, try the pliers. It will be difficult keeping the points lined up on the tiny end of the springs. Using a knife, pin, or dental pick your thumb pressing on the other side of the bolt is enough to keep them from spinning.

LikeLike

LikeLike

P.O.F. ( Patriot Ordnance Factory) makes a Roller Cam Pin upgrade Kit that helps reduce friction & drag

LikeLike

Another useful tip:

When cleaning an AR, clean the barrel from the back, not the front. You may need to add another rod section, or a suitably long one-piece rod (best). Put the patch in from the chamber end, push out the muzzle, and remove the patch. Do as little abrasion as possible to the all important muzzle crown which is hidden by the flash hider.

This is generally true for any firearm where this is possible to do.

Soldiers playing “butter churn” cleaning from the muzzle with a steel GI cleaning rod quickly wear the muzzle crown into a long cone shape. (aiaiaiaia!) Accuracy is subsequently (HONK!)ed.

LikeLike

prefer X to XV (~_^) But I should aughta look and see if things are staked on the one I know of.

LikeLike

As ever, remember to secure the cats elsewhere before disassembling any firearm. Because the buffer springs make THE BEST cat toys, whether you want them to or not!!

LikeLike

Minor lefty freakout of the day –

Florida Congresswoman Anna Luna has a short (couple of seconds long) video wearing a “Make America Great Again” one-piece bathing suit. Lefties were OUTRAGED! OUTRAGED, I tell you!

She says that she’s appeared in Maxim before, so I think it’s safe to say the voters knew about her doing things like this before they elected her.

LikeLike

The gas key is a problem because it was badly designed. Using screws in shear on a highly loaded part was brain-dead. The key should have been located by a step or dovetail to take the operating load; the screw, if any, would only keep the key from falling off.

LikeLike

Is it heavily loaded, though? The bolt carrier is driven by gas pressure from inside, not by the gas key. It’s just a tube that conducts gas from a port in the upper receiver into the bolt carrier.

LikeLike