Bearings make the world go round by The Phantom

It occurred in a blog post at Small Dead Animals regarding windmills and why so many of them seem to be broken, that people generally don’t understand how basic machinery works.

This is entirely expected. Education, in my Boomer generation and ever since, does not talk about machinery. At all. I believe this to be part of the hidden class-warfare against the Commoners in our society, the sort of pervasive disdain for plumbers, carpenters, mechanics and workmen of all sorts that permeates the media and Academia, but that is a topic for another day.

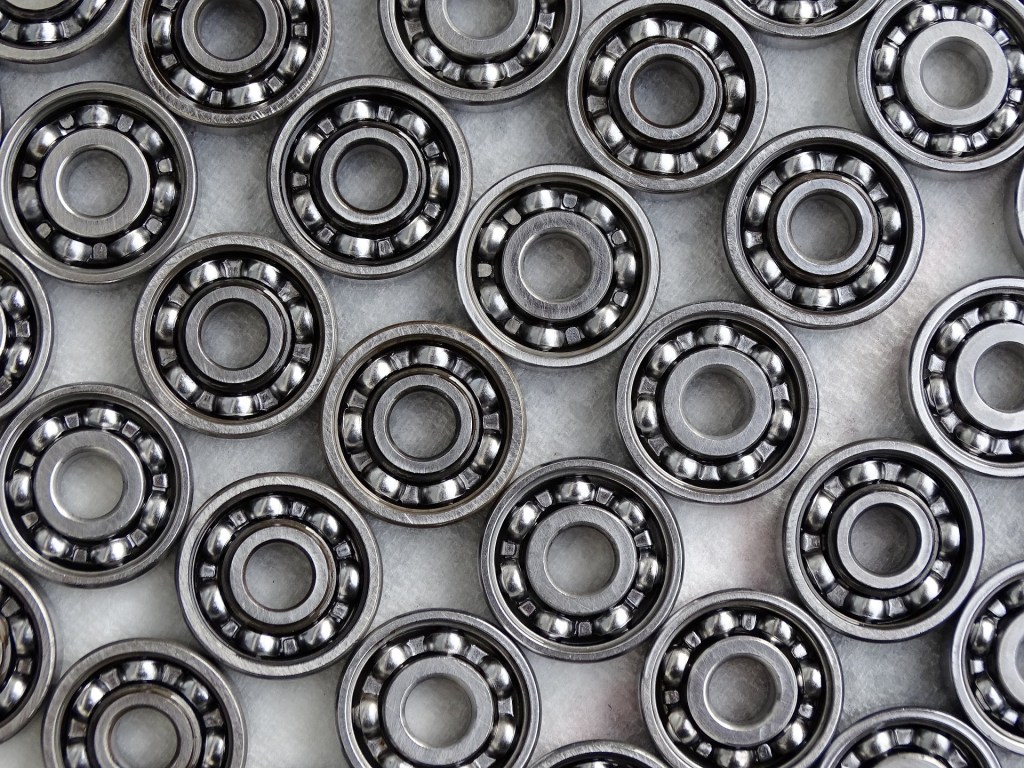

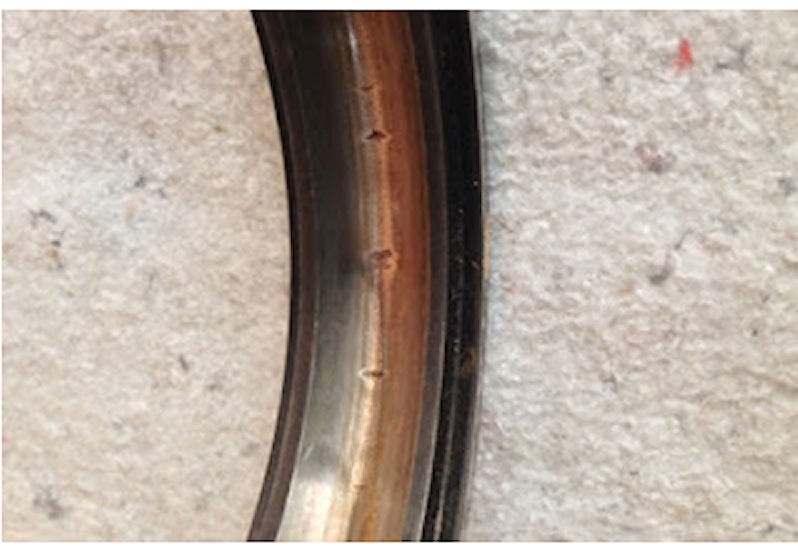

Today’s topic is bearings.Dead windmill in PEI. See that brown crap on there? We’re going to talk about that later.

Ten thousand years ago, some guy in ancient Sumeria got sick and tired of pulling a big bag of wheat behind him on a travois. That’s two sticks tied at one end and pulled along, dragging on the ground.

That un-recorded genius decided to put something that ROLLS on the end of his travois. So he whittled a piece of wood round, put a hole in it, and invented the wheel. He also invented the axle and the bearing, but nobody talks about that.

And then, after a little while of enjoying the beauty of reduced friction that the wheel brings to our lives, he discovered that his wheel had worn the axle in half because his bearing really sucked. His next invention was probably grease. Remember that, it’s important.

(Truthfully the first wheels were probably potter’s wheels, but bear with me, I’m on a roll.)

It took a long time for his idea to take hold, but eventually animals and people pulling carts became the way of the world. Humans got really good at wheels, axles and bearings. They made them out of special harder wood, and eventually out of bronze and even iron. And they used grease too.

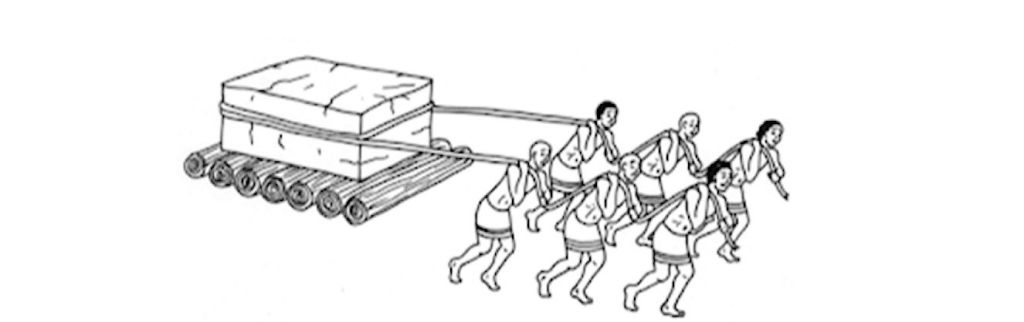

Fast forward a pretty long time, and we find the Egyptians using logs to move huge blocks of stone. Everybody knows this, right? Of interest here is that everybody spends a great deal of time focusing on the logs. Nobody seems to realize the log is only half the story. The other, and more important half is the ROAD they’re pulling the block along. That can’t be a dirt track. You get a ten ton rock and try to pull it across your backyard, the first thing that happens is the logs dig into the dirt. Those roads in ancient Egypt had to be smooth, they had to be flat, and they had to be hard. They also had to be cheap to make and maintain. That’s important as well.

Fast forward a little farther, and we find that the Romans got really good at roads. Whatever the Egyptians did to pull off their moonshot, building the Pyramids, the Romans copied it and conquered Europe with it.

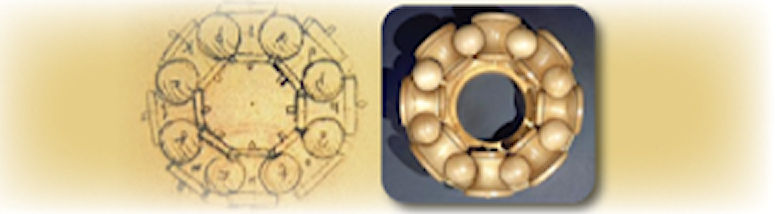

Probably not coincidentally we find the first use of ball bearings that we know of. ~40BC, in a luxury ship recovered from Lake Nemi in Italy. Used to make a rotating table, of all things. Probably fantastically expensive, because both the ball and the track that it runs in must be smooth and hard and flat. You really can’t get a round track flat and smooth without some pretty special tools, and the fitment has to be just-so. Not too tight, not too loose. The balls were metal, the tracks were wood. Super expensive custom work.

Fast forward some more, we find detailed drawings of ball bearings and bearing races from Leonardo DaVinci and Galileo. Their designs were wooden, and Leonardo included spacers between his bearings.

John Harrison invented the caged roller bearing in 1740. Philip Vaughan patented the first ball bearing system in 1794, for trains.

Of note is Isaac Babbitt of Massachusets, who developed his famous Babbitt Metal for use in poured machine bearings in 1839. The majority of industrial machinery and trains, boats etc. used poured bushings in their moving parts because that was the only way they could get enough precision at an affordable cost. Pre-1940s cars all have Babbitt bearings throughout, except for wheel bearings. Babbitt won the race for a long time not because it was the best, or the longest lasting, but because it was Good Enough and it was cheaper.

After that, FAG began precision grinding bearing balls in 1883. In 1898 Henry Timken received a patent for the tapered roller bearing. In 1907 Sven Wingquist patented the self-aligning spherical ball bearing and race. After that, everything switched to ball and roller bearing because Babbitt wasn’t cheaper anymore, and also because roller and ball bearings were better. So much better.

It’s fantastically expensive. Affordable only because they make many, many units. But as one might imagine, you do not want to have to change out that bearing. It’s meant to last the lifetime of the machine.

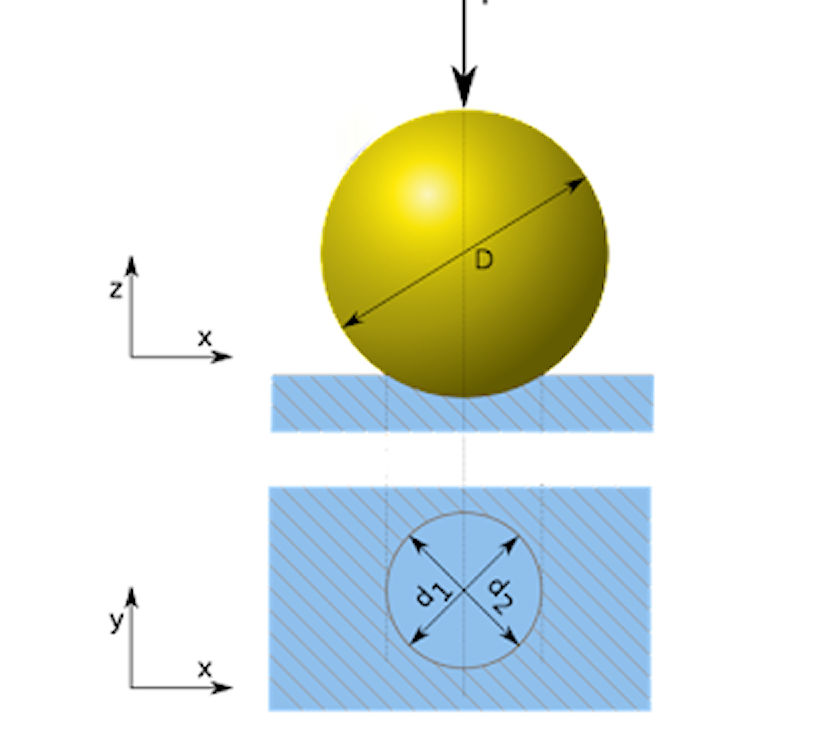

Which inevitably leads us to all those idle windmills around the country, and the reason they are idle. Brinelling. Named after August Brinell, the creator of the Brinell Hardness Scale. Long story short, Brinell tested hardness by pushing a metal ball of known hardness into a metal surface with a known amount of force, then measured the diameter of the dent it made. The harder the metal, the smaller the dent.

It turns out that if you load a ball bearing or roller bearing with a static weight, the balls or rollers will make a dent in the races just like a hardness tester. Particularly if you bang on it, or vibrate it. That’s Brinelling.

Brinelling occurs in windmills if they stand still. This is because although the roller is large, the part that is touching the race is very small. Just like the log digging into your lawn, the roller will dig into the race. Think of a knife pushing down on a piece of cheese. You don’t have to push very hard, because the knife is thin. The cheese will hold up your finger, but not the knife.

Under the types of loads common in the largest windmills, hardened steel will behave like cheese. It’ll bulge, flatten, dent, bend, do all the sorts of things you don’t want it to do. This problem is solved the same way our ancient Sumerian fixed his problem, grease. In the windmills they use oil pressure to keep everything rolling nicely and keep the bearings from digging into the races. If the windmill has to sit still for a while and be buffeted by the wind, it can survive if the oil pressure is kept up.

But if the reason it is sitting still is because the oil pressure failed? Oh, that’s bad. Because now your 20 foot diameter main bearing race has divots in it, and your six-inch rollers are all flat-spotted, and she ain’t going to roll no more.

According to the CBC article we were talking about way back at the beginning, six out of ten windmills installed at a Prince Edward Island wind power facility in 2014 are now defunct. Busted. Not turning. No word on why from the Powers That Be. The CBC is mystified. What could it be?

Brinelling. That’s what.

Bearings make the world go round — unless the world makes the bearings go flat. :-P

LikeLiked by 1 person

Excellent and informative.

LikeLike

Comment for Brinelling

Great post!

LikeLike

I find your explanation to be cogent and well thought out.

Which means TPTB will completely disregard it.

LikeLike

I actually got to do some work for TImken about thirty years ago when they were opening a plant in Virginia. My employer got hired to set up their computer systems so I had to go to Canton, Ohio for a couple weeks to meet the team and then go to the new plant every day for a couple months. I actually learned a bit about the simple, humble wheel bearing, which is what the new plant was making–some fancy new variant that had something to do with ABS systems. But I didn’t have anything to do with the manufacturing side, which was too bad, because they had all sorts of very interesting machines (CNC or whatever the equivalent was in the early ’90s) to make them. I just dealt with office crap, and unsuccessfully tried to flirt with the hot redhead office manager.

Also, their main plant in Canton looks like something right out of Boardwalk Empire–massive, brick, grungy, very American industrial circa 1920. And Canton was a real dump. Not the worst or most dangerous place I’ve ever stayed, but if it wasn’t for the Pro Football Hall of Fame, there’d never be a reason to go there unless to get gas on your way to or from Cleveland.

LikeLike

Bearings are the major reason Russia is in such deep doo-doo in logistics right now.

They don’t have a lot of internal bearing production capacity – Russia mostly used imported bearings from places like Germany. That means that, every time a tank or a railroad train had bearing problems, they got removed from service instead of being repaired.

That’s also why we never saw that massive wave of “reserve” Russian tanks that was supposed to arrive in late 2022. All of those old (and not-so-old) armored fighting vehicles that were sitting in huge tank parks, cheerfully Brinelling and converting back to iron oxide…

LikeLiked by 1 person

Don’t forget the McKinley Presidential Library and Museum, along with their Mausoleum and the First Ladies’ Museum, all in Canton…

LikeLike

Liked this post – it’s really informative. I knew nothing about windmills – now I know why they don’t work well!

LikeLiked by 1 person

Oh fascinating! Thank you for writing this, and to Sarah for posting it. I despise those bird chopping, bat killing eyesores. Hopefully they will be a thing of the past soon.

LikeLiked by 1 person

On our trips we see a lot of windmill farms. A lot of windmill farm where the windmills are not turning. Some places (cough, cough, Columbia Gorge, or Idaho plateau) it is because of too strong winds, not storms, just constant strong winds, with stronger gusts, too high for the wind turbines to function. These areas are Known for these types of wind. Other areas it wasn’t as clear why some windmills weren’t turning when others were. Didn’t know to look for the “red” on top (although given where those farms were we’d speculate the dead windmill had failed because it ate an eagle or more).

We also see a lot of solar panel farms on our trips. We know those fail and cause problems too. (Cousin’s new wife’s family farm, and their neighbors, also farmers, are really, really, really, not happy with the farm that allowed a solar farm on their acreage. Every single time it goes on or off line, it trips the power grid. Which takes hours to days to be fixed. That is hours and days without power for the farms. No power for their wells. No water for their acres, their greenhouses, their barns, and their homes. Most have resorted to backup generators for homes and stock (usually same home well), and greenhouses. They are installing small solar, not tied into the grid, for the field wells.) The difference with solar farms, can’t tell if they are working or not, as we fly by on the freeways and highways.

LikeLike

They had a rather large Solar farm in western Nebraska, Had is the optimal word. One Hail Storm came through and now you have acres of toxic junk sitting in a field. Solar panels can work on a small scale, and they can work well in outer space where there is no atmosphere to dilute the sunlight. But on a large scale you are asking for trouble. Its not cost effective and the return on your investment is minimal, and once again the manufacturing carbon foot print is never over come.

LikeLike

The location for cousin’s new family farm is just southeast of Portland Metro. Huge destructive hail storms are not going to be a problem. However the ones east of Bend? Not common, not unheard of. I have heard of the problem in other areas.

LikeLike

They were touted as being hail proof, It’s not nice to tease mother nature.

LikeLike

There is not much that is proof against baseball-size hail hitting the ground, or anything on it, at approximately terminal velocity, as the news article I read about that solar farm pointed out. ;-)

LikeLike

Solar panels are ideal for parking lots, where they can provide shade and power all at once. (At least in my area, where summer = constant sun, therefore solar ——> AC is perfect.)

LikeLike

Once again that is on a small scale. There are some ranches that have solar power electric fences. I could see you making a windmill smaller to feed an individual farm or ranch. That would be doable. Use submarine batteries to store it and a propane backup generator. Hell most farms already use propane from tanks to heat their water and homes. It would also get rid of thousands of miles of transmission lines and Transformers and other gear.

But large companies don’t get government handouts for that. Nor do they get publicity fooling the fools on the left. It would also make those ranches and farms more independent, something this current criminal Nazi government does not want. Seriously, I hope all the liberals took the clot shot so we don’t have to worry about them anymore, they would have been killed by their own stupidity. A poetic end to their worthless lives.

LikeLike

Small windmill, and solar panel, individual and combo installs exist and is happening. Note “off grid” building. More than a few have explicitly compared what they would have had to pay to have power lines (forget natural gas lines, not an option) ran (if the power companies would run the lines) VS small wind turbine combined with solar (with propane backup), with warranty, is considerably less expensive. Then they Own their equipment.

LikeLike

Get rid of Transfo0rmers? But then who will protect us from the Decepticons?

LikeLike

Right? Right?

Optimus Prime!

LikeLike

Where I grew up, you can still find some of the old, much smaller, windmills. Usually they are long defunct. Even in their heyday, they would typically only power a pump in a well. It didn’t take much if any convincing to get people onto grid power when New Deal rural electrification grants came through. Propane heat is still very common, though, as is a well and a septic tank. Even when other infrastructure exists, it’s usually connecting two elsewheres, resource on one end and populous on the other. They typically don’t want to bother with a one-off halfway.

That’s the history. I’m not aware of any current govt program for wires on poles. There’s a private power co, and a co-op for the rest. Co-op stays in the black – used to go to their annual meetings. I suspect if we had to start over, they would be organization and fund enough. Same story with phone and internet access. Private groups managed just fine without a New-New Deal of any color.

LikeLike

See, that’s what the ‘visionaries of alternative energy’ never seem to grasp. Weather in many parts of America is REALLY changeable. A few places can count on fairly constant weather (When my Navy son was stationed in San Diego, I use to ask him, “How’s the weather?”, a common topic of conversation in Northern OH. After a few calls, he finally said, “The weather is in the 70s and dry. It’s almost ALWAYS the same. So, can we talk about something else?”).

That’s why the farming Midwest stocks up on generators and listens to the weather reports. Their crops can be destroyed by storms, hail, high winds, tornados, floods, and other periodic disasters.

Wind is fine for a SMALL mill, one that can be rebuilt by the owner, if taken down by bad weather. Can’t really depend on it for flawless continual performance, particularly if it is tied to the overall grid.

And, if it is hit by a weather calamity, the cost of repair (both parts and labor) is huge. IF they still make the parts, or can get them in time from far-away places.

LikeLike

“Windmill Cemetary”

LikeLike

Neat article, thanks!

I have a 16 inch lathe (Reed-Prentice), age unclear but I’m guessing from around 1930. It has two big Babbitt main spindle bearings, lubricated by oil cups that have to be refilled every time I use it (and then some more every half hour or so). Later models have roller bearings.

An interesting alternative to roller or Babbitt bearings is oil film bearings, or their high speed low load cousin air bearings. Oil film bearings are great for extreme but reasonably constant loads and fairly slow motion — you find them in large telescopes, like the Hale telescope at Palomar.

LikeLike

I’ll have to go dig up the details again, but apparently one of the big advantages allied air power had during WWII was we had excellent plain bearings for our engines. I believe it was lead plated silver bearings or something like that.

But they did not require the complexity of rollers and could hold up to some pretty insane abuse. I think it was the plating that was the big breakthrough too, because every time the Germans recovered a dead allied engine they saw the base material, and just thought the plating was impurities, so they never tried to use that type of bearing themselves.

I believe it was discussed in SAE R241 R-2800 Pratt & Whitney’s Dependable Masterpiece.

Bearings were one of the areas the German Luftwaffe has some major issues with.

LikeLike

SAC also liked to bomb ball bearing factories whenever the opportunity presented itself.

LikeLike

There’s a lot of debate about how effective that actually ended up being. However hitting their fuel did a number on them.

At least according to Greg’s Airplanes and Autos’ research, the German synthetic high octane gas had a wonderful ability to get past seals when used in anything higher than lean operation. So something that in theory could have been 130 octane gas could only be run at the equivalent of 100 octane, when the allies were running 145+ stuff.

LikeLike

I’ve read that the major error in bombing the ball-bearing plants was that we used high-explosive bombs. Those would tear up the buildings, but didn’t do much damage to the machinery. What was needed was incendiary bombs, to set fire to the machines’ lubricating oil. Good hot fires would destroy the machinery where high explosives would just scar them.

LikeLike

One of the problems was that in their pre-war studies, the Army had simulated a factory that had a central engine and used mechanical transmission to transfer power to the individual machines… which was starting to be outdated even when they did the tests.

Upshot is, it takes far less damage to knock out such a plant than one where each machine has its own electric motor. A plant with a central engine was both more fragile and took more effort to repair when it was damaged; this meant the Army was more likely to believe they’d shut a plant down with less damage, and badly overestimate how long it would take to repair.

LikeLike

Not that it has much bearing on today’s windmills, babbitt is still available, even through Amazon.

No babbitt bearings don’t last forever but they’re easily replaceable, easy to, recast.

LikeLike

the 1964 movie The Train with Burt Lancaster playing a WWII French railroad supervisor has a 2-3 minute scene in which Lancaster’s character casts a Babbitt bearing to repair a locomotive. Whether they actually used Babbitt material for that scene I do not know but the process is simple enough that it was possible to incorporate it into the movie

LikeLiked by 1 person

First, excellent post; thanks, Phantom! But now…

I nominate this reply, specifically “bearing on today’s windmills” as co-recipient, along with “I’m on a roll” and “Babbitt won the race” from Phantom’s post, as “Best Subtle Puns in a Technical Exposition”. Even better if unintentional! Applause! :-)

LikeLiked by 2 people

They win a carp. Delivered by carptapult.

LikeLike

:-)

LikeLike

It’s nice to be appreciated when I’m punny. ~:D

LikeLike

Very cool essay, Phantom! Did not know a lot of this stuff.

LikeLiked by 1 person

Perhaps off topic, but another thing schools don’t teach? The simple balance equation. In – out = change. It applies to all kinds of things. Apples, eggs, pounds of butter, gold, or tuna, gallons of water or hydrogen hydroxide, and even dollars and cents. It helps somewhat to have a concept of negative and positive numbers to know that negative change is a decrease and positive change is an increase in what you have on hand, but the concept is intuitively simple. And mathematically, positive and negative numbers are simpler than common fractions. So why are they not taught first? Well they weren’t when I learned them. I think the whole elementary math curriculum needs to be rewritten.. and not by specialists in either education or mathematics (because both have already tried), but by someone who knows both the theory and the practice of how numbers are used.

LikeLiked by 1 person

Oh. The times I’ve heard “we’ll never use this” in math class! Dad, and we did the same for son, always showed how whatever math was being taught in school was applied to the real world.

LikeLiked by 1 person

Our physics teacher once had me do a guest lesson, so I went through the physics and math of flying from here to there, and why knowing vectors, friction, and other things was vital. Several kids boggled at how much math was involved in going in a straight line in an airplane.

LikeLiked by 1 person

Well, there is also math the process of flying an aircraft downward into the ground. Catastrophic failure of a structure is not the first lesson in solid mechanics 101.

It is not just the applied mathematics people that we owe a debt to.

Aeronautical engineering owes a lot to a great number of experimentalists.

LikeLiked by 1 person

Yep.

LikeLike

Fractions are as old as mathematics. Negative numbers came much later. Perhaps they are not so intuitive as you think.

LikeLike

The road roller, human drawn or mule/donkey drawn, is also an ancient invention. We know the Romans had them, but presumably other ancient peoples were doing it somehow.

LikeLike

The windmills also have transmissions that are problematic we have all seen the videos of windmills that catch fire on the web. Those windmill transmissions are full of hydrocarbon transmission fluid. Add to that the lubricating oils and you have something that can’t work without OIL Based Hydrocarbon fluids. We are not talking about a quart or two, but gallons of the stuff. So much for going green, because those fluids have to be changed every once in a while. You don’t, and the fluid breaks down and could cause a fire. So you can’t have a GREEN Wind Mill without Fossil fuels. I have to laugh at every Green nut when they say windmills are green. Their carbon foot print, from manufacturing to construction to their use, is fueled by Fossil Fuels. They would have to run continuously for twenty years just to break even. So every windmill has a giant carbon foot print and I dare you to find one that has run for twenty years.

LikeLike

I doubt the tech is much older than the quarter-century.

In ’19 I was an approving officer in the NATO mission’s engineer shop, New Kabul Compound across the street from the “Green Zone.” In Kabul, Afghanistan. I’d review the projects the Afghan version of USACE wanted to build with NATO money, and tell them where they were over-budget, and only approve it to send up once it was trimmed to an affordable size. The most memorable project I was sent involved a security wall with solar-powered guard shacks–running up the hillside north of Kabul’s airport. As originally suggested it wasn’t even in the same low orbit as the required budget. On the grounds that “solar won’t work there and we can’t maintain it,” I vetoedthat feature outright. I think it cut the price to a third of the initial proposal or less. Still over-budget, but not ionospherically so any more.

LikeLike

Mere words cannot express how much I love this post. 💕💕💕

So interesting and informative!

Thank you very much!

LikeLiked by 1 person

*writes the sequel- “Bearingms are a #$@#$ to remove from a Subaru CVT

LikeLiked by 1 person

I learned something today and any day you learn something is a very good day. thank you, I’m starting to appreciate why steam trains need such copious amounts of lubrication.

LikeLiked by 1 person

Ah yes, the disdain for the Working Class. My dad – a better engineer than any with a degree – who worked as a machinist and welder at a place that made weather measuring equipment for 50-plus years, would often roll his eyes at the ridiculous designs the engineers brought him, then explain materials science to them. “Sir, this won’t work because this metal doesn’t DO that. It’ll break within a week.” Inevitably he would win his argument, sometimes after the engineer insisted on trying it anyway.

After retiring, Dad’s done some work over the last few years involving precision metalworking for custom ball bearings, and while the man doesn’t swear, he got about as close as he ever would while working on ’em.

But the disdain goes both ways. My brother’s had to overcome prejudice at several internships against engineering majors by proving that he learned Dad’s lessons about materials well, and that he understands how things work both conceptually and practically.

LikeLiked by 1 person

One reason I looked up to my dad as a mentor is related to your point, but in reverse. He was an ME professor, with a physics degree. His specialty was precision measurement, so he had a lot of interaction with skilled craftsman building precision mechanisms, machine shop operators constructing them, and so on. He treated each and every one of them with the utmost respect, in effect as professional peers. That stuck with me ever since.

LikeLike

I was once building a special machine that had a plate about 3 foot square as a base with a ball bearing built into it a big as would fit – about 2 foot 8 inches in diameter. I cut the race with a slightly undersize with a 3/4″ ball nose endmill TILTED slightly so it didn’t have a line in the bottom where the flutes met. I cut both sides and assembled it with 3/4 balls and painted it with oil and a very fine abrasive. After rotating it under a light load a few hundred turns both ways I disassembled it and very thoroughly cleaned out all the oil and abrasive and threw the balls away. When we assembled it we used new balls liberally coated with Tuffoil Lightning grease.

While it was sitting there ready to assemble one of our supply guys looked at that amazed. He said- “I didn’t know you could make bearings like that. I thought you had to BUY them….

Think on that.

LikeLiked by 1 person

He’s the spiritual brother of the people who think meat comes from the store, as does milk, and are shocked to discover that there are animals involved. Facepaw

LikeLiked by 1 person

Oh, I shocked the aquarium store employees once. I was looking at some of the tropical fish. Now I am a scuba diver, and Caribbean fish was one of my specialties, I have a card and everything. (LOL) So they were trying to tell me about the fish, and I replied with telling them what the differences were for make and female, what the juveniles looked like, and what they liked to eat.

Teens=”How do you know all that stuff?”

Me=”Oh, I’ve seen these fish in the wild.”

Blank looks from the teenagers. “What do you mean, in the wild?”

Me=”The ocean. Where did you think the fish come from?”

Teens=”The warehouse.”

Not enough facepalms on the planets.

LikeLike

”The ocean. Where did you think the fish originally come from?” FIFY

In their defense most aquarium fish are not wild caught, now. Instead they are bred. There are now specialty genetically bred aquarium fish that have never existed in the wild. But those teens should have been trained on these differences and why. Supposedly it is a huge deal for aquarium fish dealer to not deal in wild caught stock.

LikeLike

That kind of thinking is what you get when guys buy everything off-the-shelf. They’ve never had to MacGyver their way to victory.

As we see from history presented above, ball bearings are a hack invented by steam-nerd Philip Vaughan because the bushings on his rail car wheels were wearing out too fast.

You can’t have a steel-on-steel bushing with a drip oiling system. The oil must be pressurized as it is in engine bearings. (For everyone else, you know why they don’t use roller bearings in engines? Brinelling. You know what happens when the oil stops flowing on your plain bearing? Kaboom. Rod through engine block. Everyone go change the oil in your car.)

Therefore you must use a bronze bushing, which will wear out pretty quick on a train. (Particularly if the drunk train maintenance guy forgets to fill the oilers, which seems to have been a thing that happened a great deal back in the day. Never underestimate the power of idiots to destroy expensive equipment.)

But you -can- have a drip oiled steel-on-steel ball bearing, and it will carry a lot more weight while lasting longer. Vaughan must have felt the breath of Hephaestus on his neck that day.

Sir, your bearing hack is worthy of Vaughan himself. I salute you! ~:D

LikeLike

Regarding the pyramids, I heard secondhand that (a) the blocks were too heavy to move manually, no matter how many people you had pulling, and (b) geologists tested the blocks a while back and found that they lacked the striations you would see in quarried limestone, meaning they were most likely poured in place like cement.

Does anyone know if these claims are true? The cement one seems obvious in hindsight, but my only source is hearsay.

LikeLike

I could get you in touch with a friend who’ll foam at the mouth and explain WHY those claims aren’t true. Would you like that?

LikeLike

I’m curious about the subject, but I don’t have the relevant background knowledge. So I’ll happily read anything that gets posted or linked here, but I can’t contribute much to a serious discussion.

LikeLike

“the blocks were too heavy to move manually, no matter how many people you had pulling”

There’s a guy who has been casting and moving blocks the size of the megaliths they used at Stonehenge by himself using pivot points and weights. On video. Anyone who claims that anything is too big to move by human power doesn’t know their physics.

LikeLiked by 1 person

I also liked the show where masons demonstrated that the secret to stones fitting together perfectly is… sanding the rocks at the building site. The more you trouble to sand them, the more perfect the polish and the fit. We just don’t bother, because we have mortar.

LikeLike

This goes back well over half a century, but between junior high and high school I had a summer job at the National Cathedral in Washington, and that was when there was a push on to finish it because the necessary stonemasons were a dying breed, and almost entirely old Italians. The grounds on the Wisconsin Avenue side were completely covered with stone blocks and plywood workshops for the masons, almost all Italians in their sixties, with a smattering of Greek, French and German masons of similar age. I tried to spend my lunch times just watching them cutting and fitting the blocks; the blocks were quarried fairly close to dimension, but final fitting took place on site. There were some ancient power grinders similar to today’s angle grinders, with the coarse grinding done wet, but the actual precision fitting was done dry and entirely by hand. There’s some mortar between the stones but it’s largely decorative and primarily to keep water from getting between the stones, not to hold it together like a brick wall would be – the precise fit between stones is what provides the strength and they are tied together at the sides and back. I was told the fit tolerances were “not quite half a millimeter” (one millimeter is .03937″ – just under 40 thousandths). Entirely by hand, and sometimes the final precise fitting was done 150-200 feet up as the individual stone was placed (FYI, each stone was numbered, measured precisely in all dimensions and logged as to exactly where on the building it was placed. I tried to get a look at the placement process, but letting a teenager near, much less into, the crane basket was verboten).

LikeLike

A good demonstration of how precisely stone can be shaped is a granite surface plate. And related, a good demonstration of how accurately things can be shaped by hand is a cast iron surface plate, which (traditionally at least) is brought to its final specs by hand scraping. A wonderful book that describes this is “The foundations of mechanical accuracy” by Moore Special Tool Co.

LikeLike

Surface plates are near-miraculous. The big cast iron ones are commonly good to less than 1/10,000 of an inch over an area the size of a sheet of plywood. Professional grade granite plates are measured in millionths, they have what is called optical smoothness.

The scraping business is also quite amazing, Abom79 has many youtube videos of doing scraping, as does Keith Rucker at Vintage Machinery.org. Mr. Rucker also has quite a few videos of replacing Babbitt bearings on ancient machinery. Fascinating stuff.

LikeLike

We had a granite surface plate in one shop that was about 6×8 feet and about thick enough to bring it waist high. Every three months the tech would come in and recertify it and hone it back flat if it was out of spec. I forget how accurate it was but the cheap on on my roll along tool box was .0002″ flat corner to corner. This was much better. We did a lot of very fussy satellite work. If it didn’t work nobody was going to run out to Clarke orbit and fix it.

One day the tech came in and I pulled my work off and he seemed irritated.

“Do you guys eat lunch on the plate?” he asked.

“No, most of us go out.” He was told.

“Well, it’s used for a table for four, sometimes six, for SOMETHING,” he insisted.

The foreman fessed up it was used several evening a week for poker.

“How did you know?” he demanded.

“You wear dips where you put your elbows.”

Mind you – this is pink granite being rubbed by shirt sleeves….

THAT accurate.

LikeLiked by 1 person

I move 2-ton granite rocks occasionally using another rock or a log as a fulcrum, and a 6-foot crowbar as a lever. Sure, they only got 1/4 to maybe a full inch at a time, “BUT IT MOVES!”

LikeLike

Yep. Levering heavy things precisely into place is a fairly common technique, one I used occasionally when a full chest freezer, among other things, needed to be positioned. I just had to be careful where I put the lever… :-)

LikeLike

Ah, bearings. I learned several ways to take apart, clean, and repack them when I was learning aircraft restoration, and later in aviation mechanic school. All were varying degrees of messy, and all absolutely vital to make the rolling and spinning parts roll and spin. Babbit was still used inside the engine for camshaft and (in some cases) driveshaft bearings. With lots, and lots, of oil.

LikeLike

Most IC engines still use sleeve crankshaft and camshaft bearings; I assume they’re still Babbit metal. Small 2-strokes are an exception; roller cranks are common there (and they have no camshafts).

LikeLike

Just don’t be the one sent out to get a quart of “relative bearing grease”.

LikeLiked by 1 person

…or “50 feet of flight line”. :-)

LikeLike

Pail of steam…

LikeLike

Or Prop Wash

LikeLike

The only reason Windmills and Solar appear to be cheaper than Fossil Fuels is because of the Government subsidies. Without them they actually cost more per kilowatt hour. So you have to pay for those green watts twice, once through your bill, and once through your taxes. Then their is the fact that they are not reliable, see Texas a couple winters ago when their much touted 17% of electric production was green and a winter storm put them all out of production. They had a failed grid during a cold snap and couldn’t provide power for lighting let alone heat. It Just Don’t Work.

LikeLiked by 1 person

Let’s change that statement a wee bit. “… because of the government stealing the money from tax payers…” Yeah, they take our money and give it to someone else so they can put up their solar panels on our dime, and we don’t get jack back for it.

LikeLike

I recall someone saying that those windmills have to turn constantly or they wreck themselves. Now I understand why.

LikeLike

Yes, the term is “cogging” which probably comes from the steam railway era. They turn the machine over slowly with electrical power to keep the main shaft bearings from Brinelling.

Which works, certainly, but it also means that your windmill is costing you money and electrical power from your grid while it is sitting becalmed. It also means that if there is a -power failure- during a time when there is no wind, there is the potential for large numbers of windmills to suffer terminal main bearing and shaft damage.

Terminal in this case means you must replace the rotating assembly -and- the oiling system because there will be powdered metal in it. Which means you must take the blades off, take the hub off, take the transmission, generator etc. off the back, lift out the old busted shaft, put back the shiny new shaft, put it all back together and test the daylights out of it to make sure you didn’t leave a wrench in there somewhere…

…and you must do all that 200 feet in the air. Which is why they don’t do it.

LikeLike

Your explanation is beautifully cogent, thank you.

But no one involved in the making cares that they don’t work because the companies paid to install them either have flown away or will get paid more to fix them. When there was accountability and responsibility, and when you had skin in the game because you were from the town and you’d be run out in a rail if you failed, that which didn’t work mattered.

Expertise is a necessary but not sufficient condition for civilization. Accountability is needed too.

LikeLike

So when these “Stop Oil” people get oil stopped, we won’t have grease for the windfarms, nor plastics abs other things needed for the super ugly solar farms. And all that energy will stop working because we stopped oil.

In the past people as effing stupid as the stop oil moron’s died because the world just ate up people who knew that little about what’s needed for people to live.

I really hate those whiny little shits because we all die if they get what they want.

LikeLiked by 1 person

And how many of those “Stop Oil” people are also vegans? They don’t realize that the animal-product substitutes they use are oil-based – plastic shoe soles instead of leather, for example.

LikeLiked by 1 person

So when these “Stop Oil” people get oil stopped, we won’t have grease for the windfarms, nor plastics abs other things needed for the super ugly solar farms. And all that energy will stop working because we stopped oil.

In the past people as effing stupid as the stop oil moron’s died because the world just ate up people who knew that little about what’s needed for people to live.

I really hate those whiny little shits because we all die if they get what they want.

LikeLike

Making the housings/races for those really large bearings is MUCH harder than making and precision grinding the rollers.

The molding/casting is quite involved, and the machining takes very special equipment. I won’t even talk about trying to heat treat that

LikeLike

They start out with a cast ingot, and then they -forge- it with an immense press. They forge it quite a lot from the clips I’ve seen on YouTube.

They take the forging and make a donut out of it by basically pressing a big thumb in the middle of it, then take the donut and roll it out to size with a ring-rolling machine. All done at white hot temperatures of course.

Such amazing technology.

The nice thing is that having developed the tech to make these immense races for windmills, they can use it to make huge rotating bearings for cranes, turbines, all sorts of things.

LikeLike

I am amazed. I learned about the Brinnel Hardness Testing about 40 years ago, as bearings are really important for hard drives. Or they used to be, as the SSDs don’t need bearings, of course.

LikeLike

Advocates of “natural, renewable” energy sources are frequently oblivious to the notion that the inputs are typically highly variable and itermittent and in no way synchronized to the demand. Thus, there is considerable buffering and storage hardware requred. Also, these sources are usually inconveniently located, which means transmission structure. And then these very same people turn around and scream NIMBY!!! When engineers try to build anything. There’s no pleasing the ignorant fanatic.

LikeLike

And when they have to lock the blades because the wind is too strong, (welcome to the west where 30MPH is a nice day) then you have to push the oil using, anyone? Power. From the grid. Which you have spent thereby increasing your net energy deficit for these pigs.

LikeLiked by 1 person

To be honest it wasn’t it wasn’t the not turning wind farm turbines we first notice while traveling the Columbia Gorge, Idaho, Wyoming, and Montana, plains (what is with the high desert plains and having the freeways traveling uphill and against the wind regardless of which direction you are traveling? I mean really!), and the phenomenon of high winds with even higher gust of winds. It wasn’t tornadoes or other stormy weather either. Clear bright blue clear sky. But the roadside reader board warnings for big trucks, motorhomes, pickups with overhead camping campers or tall canopies, and passenger vehicles towing (especially RV’s), pull over and wait out systemic high winds with gusts of 45+ MPH. When you are in a Chevy 4×4 1500 towing a trailer, one pays attention to those warnings. We typically slowed down trusting the leveling and sway bars, never had any trouble. Now that we don’t have the RV setup anymore, we point and laugh at the not running wind turbines. To be fair, heard the turbines, working or not, are good revenue for the ranchers, in areas that is acres per cow/calf, and not cows/calves per acre.

LikeLike

Yep, and not only that, but those windmills and thus those bearings are being put up in very hostile environments, such as oceans, i.e., salt water and thus salt water spray, and very cold areas where the grease thickens and the metal gets brittle.

There is a reason why the industrial revolution went from windmills to various forms of combustion engines to generate energy.

LikeLike

Give the Watermelons more time, and they will advance us from electric lights to renewable, natural beeswax candles.

Carefully rationed of course.

LikeLiked by 1 person

What did the socialists use before candles?

Yeah.

LikeLike

The Reader was thinking they’d go for whale oil lanterns.

LikeLike

It’ll be bug oil. Made from crickets or some such, and it will smell -hideous-. But it will be ever-so environmentally friendly, you know.

LikeLike

Riffraff did not get candles. They got rushlights sometimes and most of the time went to bed when it got dark. Thus conserving calories so they didn’t have to eat so much.

LikeLike

Your post reminds me of the James Burke Connections series.

You can’t do much better than that model for explaining the hows & whys of technology to those who haven’t had to learn by working on it themselves.

LikeLike

We raised our boys on Burke’s Connections, and later The Day the Universe Changed series.

Fantastic views of history and technology.

LikeLike

Woohoo! A mention of James Burke (not that one). Those were my favorite PBS series and books growing up. A fascinating narrative of the history of science and how one thing led to another. Nobody invented anything out of the blue, it was just constant improvements. Until now, unfortunately, where our betters seem determined to undo all the progress we’ve made since the Industrial Revolution. Or since the Stone Age.

LikeLike

Ah, yes, bearings.

This post put me in mind of the infamous Red River cart, which I believe to have been invented by a very senior minion of Satan. It was a two-wheeled cart made entirely from materials found locally in the northwestern prairies, as all metal had to be imported and was hideously expensive.

The axles had no proper bearings at all; instead, they were wrapped in wet buffalo-hide thongs, known as ‘shaganappi’. No grease could be used on the axles, as the prairie dust would quickly turn it to oily mud and seize up the works. As the wheels turned, the friction of the shaganappi made a screeching sound which has been compared to an untuned violin, but it was painfully loud. People travelling on these contraptions always had to bring extra wood and buffalo hide along, because the ungreased axles broke with great regularity and had to be replaced. I have read that a convoy of Red River carts could be heard for miles across the prairie because of the hideous noise.

Just a little sidelight on what happens if you don’t have bearings.

LikeLiked by 1 person

Takes us right back to our old Sumerian guy and his travois, eh? ~:D Wood-on-wood bearing, no grease. Noisy!

I remember being told about Red River carts in school as a little kid, they were Canadian so the schools never shut up about them. I do -not- remember ever being told how they were made.

I looked up the Wikipedia article, there is a great deal of PostModern bullsh1t woven into that thing, eh? Amazing how the DIE crowd can infest even a technical article about a wooden cart.

LikeLiked by 1 person

I first learned some of the details about Red River carts from Pierre Berton’s The National Dream. For the non-Canadians present, that was a book about the building of the Canadian Pacific Railway; and of course the opening chapters set the stage by describing the Canadian west before the railway. Here is Berton on the Red River carts, and why the streets in the pre-railway prairie towns were so wide:

The book and its sequel, The Last Spike, were made into an excellent miniseries in the 1970s, narrated by the author. After being unavailable to the general public for many years, the series has finally shown up on YouTube. Here’s the first episode:

LikeLiked by 1 person

I grew up near the Timken plant near Canton.

In winter, the lights from the plant would illuminate the front yard at night, and my father would shoot the rabbits crossing it.

That was back in the early’60s. Life seemed a lot simpler back then.

LikeLike

This is such a brilliant post.

LikeLiked by 1 person

Isn’t it?

THANK YOU Phantom!

LikeLiked by 1 person

You are entirely welcome, O mighty blog mistress. ~:D It’s my pleasure.

LikeLike

Growing up in a mechanic’s house, bearings and lubrication was something I learned about at an early age.

Building my own bicycle starting with turning an old German made frame into a Candy Apple purple “Stingray” clone involved taking apart a hub with internal brakes and LOTS of ball bearings

Later I go to see the FAG Kugglefischer ball bearing plant. That was the big factory at Schweinfurt Germany the famous “Schweinfurt Raid” failed to destroy in an attempt to immobilize the German war machine.

I got to hear stories about that from the locals while stationed there 78-82.

They built a fake factory closer to the path the bombers would take and let it take the pounding instead of the town…

Coincidentally, I also have, in my vintage tool collection, a “Babbitt scraper” which is a triangular rod hollow ground so that it has three edges to true up the cast Babbitt metal to match the shaft it supports. Usually the crankshaft of an engine.

LikeLiked by 1 person

So it is worse to lose your bearings or your marbles?

… I’ll see myself out.

LikeLike

I don’t have my bearings, but I’m keeping all my marbles under lock and key.

LikeLike

If you’ve still got your marbles you can take a new bearing. ~:D

LikeLiked by 1 person

Talking of windfarms, it seems that Siemens, which makes many of the turbines in them, is in some financial pickle due to things not working properly. Not clear on the details but I would not be surprised to discover that bearings were a part of the problem.

AIUI the other turbine manufacturers are also in trouble too.

LikeLiked by 1 person

https://www.insurancejournal.com/news/international/2023/06/26/727298.htm

“Most of the issues revolve around Siemens Gamesa’s 108 gigawatt (GW) onshore turbine fleet, where the group has discovered quality issues in certain components, including rotor blades and bearings.”

LikeLike

The major issue, in my humble non-financial wizard/non-engineer guy opinion, is that the manufacturers have been pushing the turbine size envelope too hard to keep the greenie weenie politicians happy. “You vant ze 300 megavatt turbine? Sure ja no problem!”

Bigger is better… until it isn’t. The difference in sheer unwieldy size between a 50 foot blade and a 180 foot blade translates to an awful lot of money, and God help you if something goes wrong with it. Warranty repairs? Oh baby!

LikeLike

No. Can’t be true! /sarcasm off

Would not surprise me if the electrical companies using the power that comes off these windmill plants either are just buying the power, and it is the companies themselves putting them in and selling the power. Plus they then have maintenance, regular unplanned shutdown/startup, and regular breakdowns, that require fixing, or replacing. Meanwhile the windmill landlord is getting paid, working turbine or not. Even if the windmills actually are being sold to electrical companies or other consortium entities, the warranty work has to be killing them.

LikeLiked by 1 person

Renewable and sustainable in practice means neither renewable nor sustainable.

‘Oh, they do the wrong things if they are not coerced to do the exactly correct thing.’ means that they have a model, and will not deviate from it on any account.

Money may be important in its own right, but is definitely a proxy for important things.

Their ‘money is not important’, and then pushing via taxation and regulation their own preferred policies has a real and important cost.

That cost including that their ‘low carbon’ nonsense is effectively a much higher carbon footprint than people ignoring them would have been. The important elements are that they are faffing around with the food supply, and we can also work out that the only way to accomplish their big official goal is to kill us all.

LikeLike

Fascinating post – thank you, Phantom!

LikeLike

Great post. And hello to all the folks involved in precision metalwork. Been in the trade since 1973. Worked on a lot of cool stuff.

LikeLike

<frowns slightly.

Your handle is my late BIL’s nickname. Threw me for a moment.

Unless you are my late BIL posting from beyond the grave, in which case find Jerry Pournelle and show him how to access the internet from there. I miss him.

LikeLike

I have been working with bearings for over 40 years. My job is to detect failure mechanisms before they become failures. This article is great.

LikeLike

High praise indeed. Thank you sir.

LikeLike

Since the problem with Brinelling occurs when the shaft is at rest, wouldn’t it be possible to invent a way to remove the weight of the shaft from the bearings- for instance, a second set of bearings that supports the shaft under that condition, designed to handle a short-term low-speed rotation, until the shaft can be braked and locked? When the wind speed warrants, the shaft could be unlocked and the force borne again by the high-speed operating bearings.

Maybe it’s not that simple, but if this is a known major failure mode, it seems that one could engineer a solution (I can think of others) rather than continue building expensive equipment destined to fail before a reasonable ROI can be realized. Unless the whole project is a boondoggle, a possibility I don’t dismiss.

LikeLike

Theoretically the machine is engineered to withstand the stresses involved. As witnessed by the fact that they don’t -all- break, the engineering is sound. Sort of.

But, witnessed by the large number of failures, you would think that the engineers would have put a yoke or something in there to take the weight of the thing in case Something Bad happened, right? Power failure, oil pump failure, seal failure, some other kind of failure I don’t even know about, wouldn’t they have a couple of collars to jack it up and hold it still so the bearings don’t get killed?

Well, apparently not. Or if they did, it doesn’t work that great. Ten windmills erected in 2014, six of them died in less than ten years? That’s going to be one hell of a warranty repair, right? And as mentioned in another comment, Siemens is in financial difficulty because of exactly this.

This has the sound of an argument between an engineer and a manager. The engineer says there must be a safety yoke at $X million dollar cost or the warranty repairs will ruin the company. The manager vetoes it because the sales department is screaming for price reductions. Manager retires long before the repairs pile up and company goes broke, right? >:(

LikeLiked by 1 person

Every engineer has seen that movie during their career.

LikeLiked by 1 person

That presumes that they got a working design for a safety yoke by the time that people were demanding their windmills.

It seems like many people may have a weirdly wrong idea how design, fabrication, and test work. You can look at a bunch of new technologies rolled out, and conclude that the sky is the limit.

But, there were real limits. Looking back, the stuff that they built was not the only things possible for them to build, but the other things they could have done instead were not infinite in possibility. A lot of the things that they tried to build were things that previous cohorts of engineers had done some related design wrok on, attempted to fabricate with the help of tradesmen and craftsmen, and then tested to the point of learning about design flaws and inherent challenges.

Engineers normally learn a fair amount by doing stuff that initially seemed like it would work, and then comes apart in execution.

That meant that the engineers might know a lot about not screwing up on that class of design when circumstances changed enough that people were willing to finance a real production run.

And when engineers know the area of practice well, and care about risk, they can be amazingly conservative with what they do.

There are some issues with that prediction for windmills.

One, for at least twenty years, the engineers have also been gaslit when it comes to the environment, and doom. You are perhaps more willing to cut corners on preventing the blade from falling off, and killing someone, if you are certain that more people will die if you can’t cut enough corners to push out a counterfeit windmill.

Two, this is pushed by politicians, who seem to be insane as a occupation.

With EVs, they have been very energetically stating timelines that appear to be complete fiction, and uncaring whether the vehicles in question are even physically possible.

So here I think you may have been a bit generous to the engineers, and assuming that they had time to figure out something that would work at that scale.

LikeLike

I get a kick out of the ‘planned obsolescence’ almost-conspiracy theory. No, as a general rule, no one designs a ‘break after X duration of use’. Trust me, we’re busy full time trying to get them all to last at least that long, while still doing the thing, and without breaking the bank.

This last part is key – If you’re R & D or government, you may be at several removes from direct financial pressure, but there are always tradeoffs.

LikeLike

Great post! I especially appreciate the pictures.

bear with me, I’m on a roll

I’m not sure if that deserves applause or a carp.

LikeLike

Embrace the power of “and”. :-)

LikeLike

Carp cannon locked!

LikeLike

Excellent post. I posted on Babbitt earlier, thought you might like to compare: https://falsechoices.substack.com/p/pouring-babbitt

LikeLike

That is an -excellent- post, Tom. So insightful. Give it to Sarah as a guest post, is my suggestion.

The disdain for the common working man and his skills is not a new thing. Probably a holdout from Feudalism, would be my un-researched guess. The nobility trying to maintain their mystique.

Of possible interest is Christopher Schwartz, who has been doing considerable work regarding what he calls “vernacular furniture” of the type turned out by working-class joiners and carpenters over the millennia. Much of which has not varied since Roman times, according to the archaeological record. Example, three-legged stools have remained the same for several thousand years.

The great museums of Europe, according to him, contain none of this history. Worth checking out his blog, https://blog.lostartpress.com/

LikeLike

Thank you for your kind review, appreciated. I used to follow Christopher when he was in his Roubo work table design phase but had lost the thread, glad to find it again, he’s a talented man who is willing to take the road less travelled. And on the suggestion of a guest post, how would I send a link to Sarah?

thanks again,

Tom

LikeLike

first two initials last name at the heated email.

LikeLike

My wife laughed when she noticed the artifact of the Pompeii traveling exhibit I was most excited to see was the bronze water valve. You just never get to see ancient plumbing in museums.

LikeLiked by 2 people

It’s not so much a holdover of feudalism as a disease of the Renaissance.

The ancient Greeks and Romans believed that manual labour was fit only for slaves, and a man of the upper classes should keep his mind absolutely free of sordid practical know-how. This attitude changed considerably when Christianity came in, partly because of the old Jewish tradition that a rabbi ought to know a manual trade and be able to support himself by it if necessary. Jesus and St. Paul were both fully qualified rabbis, entitled to preach in the synagogues, but the one was trained as a carpenter and the other as a tentmaker. They did not look down on craftsmen, or on slaves for that matter; and the early Church, unlike most religious movements of the day, accepted both groups as full members.

But in the Renaissance, the upper classes thought it terribly fashionable and high-toned to turn up their noses at ‘barbarous’ mediaeval innovations and go back to the allegedly superior ways of the ancients. These superior ways included absolute monarchy, judicial torture, and worst of all, the revival of slavery – and with it, the old contempt for working with one’s hands.

LikeLiked by 1 person

“and with it, the old contempt for working with one’s hands.”

Which persists to this day among the self-identified elites.

LikeLiked by 1 person

Indeed. The leading figures of the so-called Enlightenment inherited that contempt without troubling to question it. Voltaire played at chemistry but contributed nothing to the science. Rousseau, like many other intellectuals, had the gall to lecture people on how they ought to raise their children, while abandoning all his own offspring to orphanages. Marx prescribed the cure for all the maladies of industrialism without ever setting foot in a factory or being responsible for any kind of business, public or private.

Indeed, it became an accepted part of the standard intellectual ideology that the affairs of the public could only be commented upon intelligently by those who knew nothing about them – since those who actually knew, and had experience, were accused as a class, without exception, of acting corruptly to feather their own nests.

Many years ago, I discovered a perfect example of this dichotomy between academic theorists and knowledgeable persons; and I found it in the books of two historians, Will Durant and Paul Johnson. As it happens, Durant left off his Story of Civilization at the Battle of Waterloo in 1815, and Johnson chose the same starting date for his book, The Birth of the Modern. But historical periods are sloppy things, and the two men covered many of the same topics in their works. Durant writes about the Industrial Revolution in sloppy generalities; Johnson writes about particular inventions in as much technical detail as he has space for. Durant writes about art from the point of view of a gawker in the great art galleries of Europe; Johnson, from the point of view of a painter, pointing out (for instance) that Turner’s famous palette, with its heavy use of whites and yellows, was dictated by the limits of chemistry at the time and the want of suitable pigments, especially greens. Durant treats Constable as a major figure in a minor genre of painting; Johnson situates him in the art of technical drawing, and makes cogent remarks on his accurate depiction of working mills. And so on.

(I have always regretted that Johnson never found the time, or perhaps the interest, to carry his story forward from 1830, where The Birth of the Modern ends. Another such volume would have brought him up to the failed revolutions of 1848, and put the ex-Communist historian face to face with his fallen idol, Marx. That would have been profoundly interesting.)

LikeLike

One of the commenters on Larry Correia’s post ‘An Opinion On Gun Control’ put forth the curious notion that Larry knows too much about guns to discuss the subject.

I suppose the rando had a point, in that only the ignorant can believe in gun control.

———————————

“Gentlemen! You can’t fight in here — this is the War Room!”

LikeLiked by 1 person

Birth of the Modern, on my list now. Thank you!

LikeLike

Back when, when the world was young, I was an electrician for some years. Of course electric motors (and generators) all have bearings as their primary moving part. You don’t install them right (which is tricky and the feedback is not immediate) and they don’t last long. It’s a skill. Electric motors are in everything. So nothing much works without them.

Also all our bearings were from SKF in Sweden. Apparently that’s an acronym for Swedish Bearing Company in swedish.

There’s a lot of different sorts of bearings of different quality but unless things have changed (and if they have I’d bet it’s in the direction of more concentration – that’s way everything else has gone) the only truly good ones were from this one source.

There seem to be an awful lot of single points of failure in our industrial supply chains and this seems to be one of them.

Great article. Thanks.

LikeLike

Timkin in Canton was mentioned several times. The produce their own steel there. Touring the steel facility and seeing the yellow hot ingots come down the rollers and get stamped with batch numbers as they rolled guys within arm’s reach was fascinating. They make seamless tubing there too. The hot bar off the rolling mill is grabbed in clamps and a guy sitting there pulls a big lever and a huge marine diesel engine PUSHES a long rod with a pointed carbide bullet on the end all the way down the center. You can see the bulge traveling to the other end.

Years ago – 70s – I used to go up in the airport control tower right by their plant. Whenever the company jet took off and the (unlicensed) grandmother Timkin was flying she loved personally doing full power take-offs. Held it well past time to rotate and then rotated so hard it’s a wonder she didn’t smack the tail and would climb out at a frightening angle. Amused the hell out of the controllers who would verify with binoculars she was in the left seat.

LikeLike

If only we had ended Soviet Russia in 1945 with Gen. Patton and FeldMarschall Rommel charging to the front, leading the way.

LikeLiked by 1 person

I’ll bite. How do you get round the bit where Rommel was already dead by then?

LikeLike

Different timeline. An inconvenient fact changed through timeline magic. We got him out, ditto Patton. Unfortunately, we had less than courageous leaders who didn’t recognize Communism as the world wide existential threat it’s become in the last 50 years. FDR, Truman, JFK. Apparently there was a Deep State Cabal after JFK, that’s been fairly well documented. The Dems should be outraged over Kennedy. GOP, much the same over treatment of Jeb Bush and Pres. Trump. He’s running again, a low exit number is expected. Anyone who votes for Bush or Biden has to have lost their mind, we’ll help them find it. I will vote in person, with validation of my vote shown to me. No, I don’t trust county officials to count votes correctly. No one in government is trustworthy anymore.

RSH

LikeLike

aye

LikeLike